The difference in parts extends beyond upfront costs alone; it also encompasses reliability, compliance, and the hidden expenses that can significantly impact your maintenance budget. Every hour lost has enormous ramifications, so your parts procurement strategy has never been more critical.

In this guide, we’ll reveal critically selected parts that transform maintenance outcomes, leading to an efficient, reliable and successful maintenance strategy for your mining operations.

Don’t lose a minute in downtime. Select premium heavy-duty parts you can rely on. Call HDD Solutions today.

Fundamental Underground Mining Equipment Parts

Key Parts for Mining Equipment |

Purpose of this Mining Part |

Why This Part is Crucial to Your Maintenance Strategy |

|

|---|---|---|---|

|

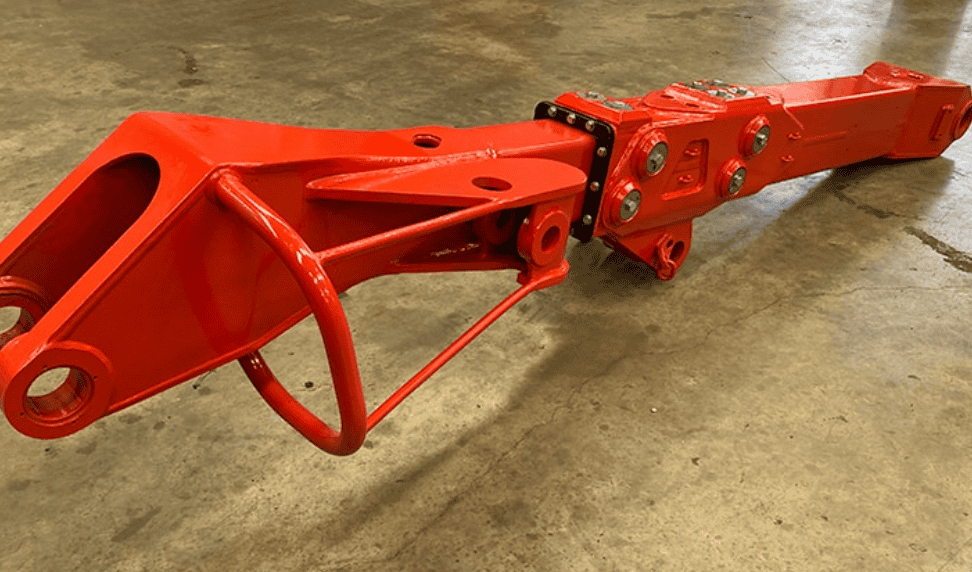

TB60 Booms |

|

|

|

Wheel Ends |

|

|

|

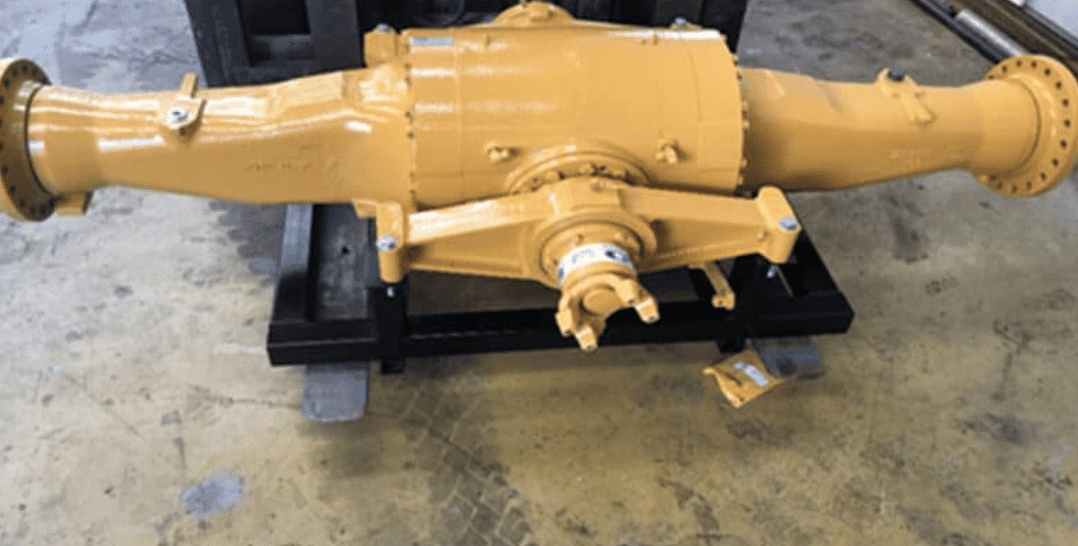

Transmission Parts |

|

|

Support Your Maintenance Strategy With Reliable Servicing

Once you’ve selected the critical parts for your mining operation, it’s essential to maintain their upkeep with regular, expert mining equipment servicing. HDD Solutions offers general and emergency servicing for all mining equipment parts. We’re particularly experienced with Caterpillar, Sandvik, Atlas Copco and Normet, but our skilled team can handle any brand on the market.

What Makes HDD Solutions Mining Spare Parts Stand Out From Competitors

Why do some of the biggest mines in Australia rely on HDD Solutions for their quality parts?

- We’re passionate about keeping our clients performing at peak 27/7.

- We only source the best. Owner Joe Stalteri leads a team of specialist diesel fitters and technicians with over 30 years of experience working with only the most premium parts available.

- We understand timing is everything. Our team works rapidly to procure what you need ASAP.

- We’re here every step of the way with outstanding technical guidance and support.

- We’re 100% committed to safety. We know a mine has to be as safe and secure as it is productive, and our parts (and expert advice) play a key role.

- Our purpose-built Wangara workshop was established in 2018 and is a convenient, easy-to-reach servicing destination for many West Australian mines.

How Do I Choose Reliable Mining Equipment Parts Suppliers in Australia?

When selecting a mining equipment parts supplier in Australia, reliability and industry compliance should be your top priorities. Start by verifying that the supplier has a proven track record with established mining operations. Look for ISO certification and operators who comply with Australian mining safety regulations (AS/NZS standards). You ideally want to see a wide inventory of OEM (Original Equipment Manufacturer) available, backed by clear warranties. HDD Solutions offers all these and more.

How Do I Verify the Quality Standards of Mining Equipment Parts Suppliers?

You should request evidence of certifications such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and AS/NZS mining compliance, all of which HDD Solutions can provide.

How Can I Reduce Mining Equipment Downtime?

Reducing downtime requires a proactive and predictive strategy that includes partnering with reliable suppliers who can provide premium-quality inventory, fast deliveries, immediate technical support, and ensure that critical parts are always available.

What Documentation Should I Require From Parts Suppliers for Compliance?

Compliance in the Australian mining sector requires suppliers to provide clear documentation, including:

- Certificates of conformity (COC) or compliance with AS/NZS standards

- Material Safety Data Sheets (MSDS)

- Warranty statements

- Test reports and quality assurance documentation.